Down Vest Manufacturer vs. Trading Company: Key Differences

- Share

- Issue Time

- Sep 17,2025

Summary

Discover the differences between a down vest manufacturer and a trading company—see why Ginwen’s ISO-certified factory, low MOQs, and real-time QC make it the smarter choice.

Introduction: Why Understanding the Difference Matters

If you are planning to launch or scale your outerwear collection, one of the most important sourcing decisions you will make is whether to work with a down vest manufacturer or a trading company. While both may appear to offer similar services, they are vastly different in terms of control, speed, cost, and reliability.

For fashion brands, outdoor labels, and private retailers, this choice can directly influence product quality, delivery timelines, and brand reputation. Working with the wrong type of partner often results in missed retail windows, inconsistent sizing, quality complaints, and rising costs.

This blog will help you clearly understand the key differences between a down vest manufacturer and a trading company, so you can make an informed choice for your brand. We will also show how we at Ginwen, as a fully certified and vertically integrated down vest manufacturer, help global brands bring their designs to market faster and with complete quality assurance.

What Is a Down Vest Manufacturer?

A down vest manufacturer is a company that owns and operates its own production facility. They are directly responsible for every stage of product development and manufacturing, including:

Sourcing and testing raw materials (shell fabrics, lining, down fill)

Developing patterns and grading using in-house CAD systems

Cutting, sewing, quilting, and assembling garments

Conducting quality control at each stage of production

Packing, labeling, and shipping finished products

Because manufacturers control every process, they can guarantee consistent quality, shorter lead times, and full customization.

At Ginwen, we are proud to operate as a professional down vest manufacturer. You can view our Custom Down Vest Collection

to see how we turn our clients’ creative concepts into high-quality retail-ready products.

Here are some of the core strengths that set us apart as a manufacturer:

ISO 9001 & BSCI certified production systems

Strong in-house CAD development team for patterning and prototyping

Massive monthly production capacity of 500,000 pieces

Automated lines covering fabric inspection, washing, cutting, printing, sewing, packaging

Real-time quality monitoring and bottleneck control

Low MOQ from just 1 piece

Fast turnaround: 7–14 days for samples, 30 days for bulk

This level of integration is what enables us to help brands launch their down vest lines on time, at scale, and with uncompromising quality.

What Is a Trading Company?

A trading company does not own a factory. Instead, they act as intermediaries who buy from third-party factories and resell to brands with a markup. Their operations usually involve:

Searching for suppliers on behalf of clients

Requesting quotations and passing information between the brand and factories

Managing orders and logistics as a middleman

While this might seem convenient, trading companies come with significant drawbacks:

No control over production schedules — they rely entirely on external suppliers

No in-house quality systems, meaning issues are often discovered only after production

Higher costs due to middleman markups

Slower communication because every detail must pass through several layers

Limited customization capabilities — often only offering stock products

This lack of direct control makes it hard to achieve consistent sizing, on-time delivery, or technical innovation — all of which are critical when producing custom down vests.

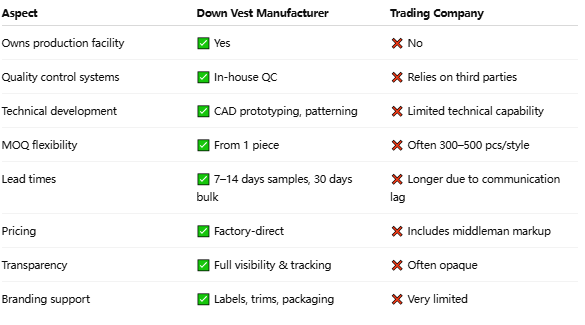

Manufacturer vs. Trading Company: A Side-by-Side Comparison

As this table shows, a down vest manufacturer offers clear advantages in quality, speed, cost-efficiency, and customization — making it the smarter choice for any brand aiming to grow sustainably.

Why We at Ginwen Choose to Be a Manufacturer

At Ginwen, we believe that owning our production allows us to guarantee reliability, speed, and quality for our clients.

As a down vest manufacturer with over 20 years of experience, we support global fashion brands, outdoor labels, and private retailers with:

ISO 9001 & BSCI certified manufacturing systems

Low MOQ from just 1 piece — perfect for samples or capsule drops

500,000 pieces/month production capacity

Automated production processes from fabric inspection to packaging

Real-time QC and bottleneck monitoring

Full private label services including logos, labels, trims, and packaging

Because we own the factory, we can deliver samples in 7–14 days and bulk orders in 30 days — something trading companies simply cannot match.

Why a Down Vest Manufacturer Delivers Better Quality, Speed, and Value

Choosing a down vest manufacturer instead of a trading company gives your brand direct access to the production floor. That access translates into better quality control, faster development, lower costs, and stronger intellectual property protection.

Here how manufacturers like us at Ginwen outperform trading companies at every stage of the production cycle:

1. Direct Quality Oversight

We operate with in-house QC teams who monitor every stage of manufacturing — from raw material inspections to final AQL checks. Our systems include:

Fill power tests to verify warmth performance

Fabric strength and colorfastness testing

In-line inspections during cutting, sewing, and quilting

Final inspections before packing and shipment

Trading companies don t’ have direct control or QC capabilities. They depend on whichever third-party factory they hire, meaning you only learn about defects after production is finished.

2. Faster Development Cycles

At Ginwen, our strong in-house CAD development and prototyping team can turn your tech packs into production-ready samples quickly. We deliver:

Samples in just 7–14 days

Bulk production in 30 days

By removing the middleman, we eliminate communication delays and help you hit your seasonal launch windows on time.

3. Lower Total Costs

Trading companies add hidden markups on top of factory prices. Working directly with a down vest manufacturer gives you factory-direct pricing and removes unnecessary overheads.

Plus, by preventing defects and delays, we help you avoid costly remakes, airfreight surcharges, and lost sales.

4. Full Customization & Branding Support

Most trading companies only offer stock styles. In contrast, we provide complete customization:

Custom baffle and quilting designs

RDS-certified down or recycled fill options

Personalized labels, trims, zipper pulls, and packaging

This allows your custom down vests to stand out in the market and reinforce your brand identity.

The Hidden Risks of Using Trading Companies

While trading companies may appear convenient at first, they carry serious risks that can hurt your brand growth.

Here are the most common pitfalls brands encounter when using trading companies instead of a down vest manufacturer:

⚠️ Inconsistent Quality

They often switch factories based on price, which results in different sizing, stitching quality, and down leakage between batches.

Without in-house QC, they can’t guarantee stable product standards.

⚠️ Missed Deadlines

Communication lags and dependency on multiple external parties often lead to delayed samples and late bulk shipments, which can ruin retail launch schedules.

⚠️ Lack of Transparency

You usually don’t know which factory is producing your goods or if they follow ethical standards. This makes it hard to ensure compliance and traceability.

⚠️ Higher Costs

Middleman markups raise your landed cost, and you still face risks of defects, returns, or unsellable inventory.

⚠️ IP and Brand Risks

Some trading companies reuse your designs, logos, or tech packs without permission, jeopardizing your intellectual property.

In short, trading companies offer neither production visibility nor accountability, while a true down vest manufacturer protects your quality, IP, and brand equity.

Case Study: How Ginwen Helped a Brand Switch From a Trading Company

One of our recent clients, a mid-sized European lifestyle brand, initially sourced their down vests from a trading company. Their challenges were:

Unreliable sizing — every batch fit differently

Late shipments that missed their winter retail season

High unit prices despite mediocre quality

Zero visibility on which factory made their products

They came to Ginwen seeking a more reliable down vest manufacturer. We provided them with a fully transparent process:

1-piece MOQ sampling so they could test new styles risk-free

7-day sample development using their existing tech packs

Real-time production tracking via our dashboard system

Full private label customization with woven labels, zipper pulls, and branded packaging

30-day bulk production turnaround for their first 3,000-piece order

The result was transformative. Their first Ginwen batch passed 100% of internal QC checks and shipped ahead of schedule. Retail buyers praised the improved fit, construction, and finishing, and the brand doubled its next order volume for the following season.

By shifting from a trading company to a true down vest manufacturer, they gained:

Stable sizing and quality

Faster delivery

Lower landed costs

Complete visibility and IP security

Why We at Ginwen Are the Partner You Can Rely On

At Ginwen, we’ve spent over 20 years perfecting our systems as a down vest manufacturer to give brands everything they need to succeed. Our factory offers:

ISO 9001 & BSCI certified production systems

500,000 pcs/month capacity with automated processes from fabric inspection to packaging

Strong in-house CAD team to support rapid pattern development

Real-time production monitoring and bottleneck management

Low MOQ from just 1 piece, ideal for samples, capsule drops, and startups

Private label expertise in logos, trims, labels, and packaging

Fast delivery: samples in 7–14 days, bulk in 30 days

Because we control every step, we can guarantee that your custom down vests are delivered on time, on spec, and at the quality your brand demands — something a trading company simply cannot provide.

How to Evaluate and Choose the Right Down Vest Manufacturer

Finding the right down vest manufacturer can determine the success of your entire product line. To help you make an informed decision, here’s a clear evaluation checklist that global brands and retailers use when vetting potential partners:

Production Ownership & Capacity

Do they own their factory or outsource to third parties?

What is their monthly capacity? (Ginwen offers 500,000 pcs/month.)

Can they scale from 1-piece samples to high-volume orders?

Technical Development Capability

Do they have a dedicated in-house CAD pattern and prototyping team?

Can they handle complex designs such as multi-panel quilting, reflective trims, and specialty fabrics?

Quality Systems & Certifications

Are they ISO 9001 & BSCI certified?

Do they run material inspections, fill power tests, and seam strength testing?

Do they use real-time production monitoring to avoid bottlenecks?

Lead Times & Responsiveness

Can they commit to samples in 7–14 days and bulk in 30 days?

Do they offer production calendars and daily progress reports?

Branding & Private Label Services

Do they offer custom logos, woven labels, trims, zipper pulls, and packaging?

Can they support eco-friendly packaging options to match your brand values?

Communication & Transparency

Will you have a dedicated merchandiser who speaks fluent English?

Do they allow direct communication and factory visits?

This checklist helps distinguish a true down vest manufacturer from a trading company. The right partner should not only produce your designs, but also help you protect your brand reputation and accelerate growth.

Step-by-Step: How to Start With Ginwen

We’ve built a streamlined process at Ginwen to make it simple and risk-free for brands to work directly with a down vest manufacturer:

Step 1 — Share Your Concepts or Tech Packs

Send us your sketches, mood boards, or full tech packs. Our in-house CAD team will review the details, verify feasibility, and propose any improvements to ensure production readiness.

Step 2 — Material Sourcing & Approval

We source and test your specified shell fabrics, linings, and down fill (RDS-certified or recycled). Every batch is lab-checked for fill power, tensile strength, and colorfastness before we start sampling.

Step 3 — Sample Development (7–14 Days)

We produce fully finished samples with your custom logos, trims, labels, and packaging mockups so you can confirm fit, construction, and aesthetics before bulk.

Step 4 — Bulk Production (30 Days)

Once you approve samples, we begin full production on our automated lines (fabric inspection, washing, CAD cutting, sewing, quilting, printing, finishing). Our real-time production dashboard gives you daily updates.

Step 5 — Packing & Delivery

We package your vests with your custom branding and perform final AQL inspections before shipping under your preferred terms (FOB/CIF/DDP). We also provide complete export documents and production photos.

Step 6 — After-Sales Support

We stay engaged post-delivery to handle size feedback, restocks, and new colorway launches — supporting your brand long-term.

This transparent system helps brands move from idea to market launch quickly, without the uncertainty that comes with trading companies.

Why Partnering With a Manufacturer Protects Your Brand

Working directly with a down vest manufacturer gives you the control and consistency needed to protect your brand reputation, quality standards, and delivery timelines.

Here why:

Reliability: Manufacturers like Ginwen deliver on time, every time, ensuring you never miss a retail window.

Consistency: Our in-house processes produce identical sizing and finishing across all batches.

Transparency: You know exactly where and how your products are made.

IP Security: Your designs, patterns, and logos stay secure in our facility.

Scalability: We scale production as your orders grow — from 1-piece samples to 50,000+ units.

Trading companies can’t provide this control. They introduce hidden risks, communication gaps, and inconsistent quality — problems that can derail your business.

Why We at Ginwen Are the Right Down Vest Manufacturer for Your Brand

At Ginwen, we’ve built our business to give brands everything a down vest manufacturer should provide. With over 20 years of experience, we’ve supported leading fashion brands, outdoor labels, and department store chains worldwide.

✅ ISO 9001 & BSCI certified

Our Key Strengths:

ISO 9001 & BSCI certified manufacturing systems

Low MOQ from 1 piece — ideal for samples and capsule launches

500,000 pcs/month capacity for large-scale retail rollouts

Automated production processes: fabric inspection, washing, CAD cutting, sewing, printing, packaging

Strong in-house CAD development and prototyping team

Full private label customization (logos, labels, trims, packaging)

Real-time production monitoring to prevent delays and bottlenecks

Fast turnaround: 7–14 days for samples, 30 days for bulk

Why Choose Us:

✅ ISO 9001 & BSCI certified

✅ MOQ from 1 piece

✅ 500,000 pcs/month capacity

✅ Automated production systems

✅ CAD development support

✅ Private label expertise

✅ Real-time QC tracking

We don outsource your designs — we produce them ourselves with speed, consistency, and care.

Conclusion: Build Your Brand With the Right Partner

Choosing between a down vest manufacturer and a trading company will shape your brand future.

While trading companies might seem convenient, they bring hidden problems — delays, inconsistent quality, higher costs, and no transparency.

By partnering with Ginwen, you gain:

Complete quality control

Faster production and delivery

Lower costs through factory-direct pricing

IP protection and brand security

Scalable capacity to grow with your demand

📩 Ready to start your project? Reach out to us today to discuss your design ideas.

Let bring your next down vest collection to life.