From Sample to Bulk: The Workflow with a Bomber Jacket Manufacturer

- Share

- Issue Time

- Oct 7,2025

Summary

Learn the complete workflow with a bomber jacket manufacturer—from sampling to bulk production—and discover why Ginwen is your trusted OEM & ODM partner.

Introduction: Why the Right Bomber Jacket Manufacturer Matters

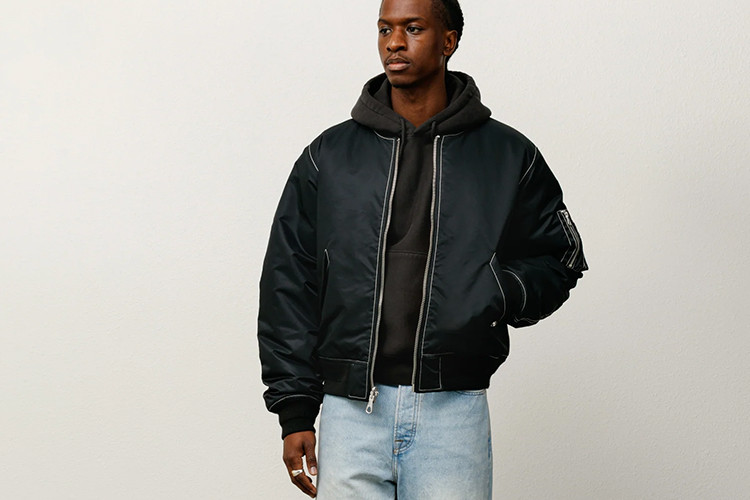

In the apparel industry, bomber jackets have become a timeless icon—bridging streetwear, luxury fashion, and functional outerwear. Whether designed for casual city life or as part of a high-end fashion capsule, the bomber jacket remains one of the most versatile garments in modern wardrobes.

However, behind every successful bomber jacket collection lies a critical partner: the bomber jacket manufacturer. Choosing the right factory isn’t just about price—it about ensuring precision, quality, scalability, and alignment with your brand’s vision.

For fashion brands, retailers, and wholesalers, understanding the workflow—from sample development to bulk production—is key to minimizing risk and achieving consistency. This guide will take you through that complete process, showing how a professional manufacturer like Ginwen ensures speed, quality, and reliability in every order.

Section 1: Understanding the Role of a Bomber Jacket Manufacturer

A bomber jacket manufacturer plays far more than a sewing role. They manage the entire lifecycle of production—from concept to shipment—ensuring that each step adheres to technical, ethical, and aesthetic standards.

Key responsibilities include:

Pattern Making & CAD Development

Material Sourcing & Fabric Inspection

Prototype Sampling & Adjustments

Bulk Cutting, Sewing & Finishing

Quality Assurance (QA/QC)

Packaging & Shipment

Working directly with a skilled manufacturer allows brands to transform creative ideas into commercial products while maintaining consistency across every piece.

Section 2: The Pre-Production Stage – Design & Sampling

Before mass production begins, every order starts with a sample phase. This stage defines the foundation of your final collection.

Step 1: Design Brief

Clients provide tech packs, sketches, or inspiration images. A professional manufacturer reviews these to assess technical feasibility, fabric options, and trim availability.

Step 2: CAD & Pattern Development

At Ginwen, our in-house CAD team converts design concepts into precise patterns. This digital process ensures measurement accuracy and consistency during bulk production.

Step 3: Sample Creation

Once approved, the factory produces a prototype sample—the physical representation of your idea. This stage usually takes 7–14 days. The sample allows you to evaluate:

Fit & silhouette

Stitching quality

Zipper alignment

Color & fabric performance

Step 4: Feedback & Revisions

After receiving feedback, the manufacturer refines the sample to achieve the exact desired outcome before mass production begins.

This phase is not just about approval—it’s about collaboration between brand and factory to achieve perfection.

Section 3: Ginwen – Your Reliable Bomber Jacket Manufacturer

At Ginwen, we specialize in OEM & ODM bomber jacket manufacturing for global fashion brands, retailers, and private label clients. With over 20 years of experience, we understand the balance between fashion design and industrial precision.

Our production systems are:

✅ ISO 9001 & BSCI certified, ensuring compliance and quality consistency

✅ Supported by a dedicated CAD & prototyping team

✅ Backed by a monthly capacity of 500,000 pieces

✅ Fully automated, from fabric inspection to cutting, washing, sewing, and packaging

✅ Equipped for private label customization, including trims, logos, labels, and packaging

We offer an accessible MOQ of 100 pieces, making it easy for both startups and established brands to bring their bomber jacket ideas to life.

Samples are developed in 7–14 days, and bulk orders are completed within 30 days, helping our clients stay ahead of market timelines.

Inside Production: From Fabric Inspection to Finishing

Section 4: Fabric Inspection – The Foundation of Quality

For any bomber jacket manufacturer, quality begins long before the first stitch—it starts with fabric inspection. A professional factory ensures that all raw materials meet technical and visual standards before entering production.

At Ginwen, every roll of fabric is inspected under strict parameters:

Color consistency – No irregular dyeing or shading differences.

Surface smoothness – Free of flaws, snags, or weaving defects.

Tensile strength – Verified to withstand stress without tearing.

Water resistance or coating quality – Tested for durability and function when applicable.

This initial step guarantees that every batch of custom bomber jackets starts with premium, approved materials.

Section 5: CAD Patterning and Automatic Cutting

Once the fabrics are approved, the next stage is CAD pattern development and automatic cutting.

Our in-house CAD team at Ginwen transforms digital templates into highly precise cutting layouts. This technology minimizes waste and ensures that all sizes remain perfectly consistent.

The automated cutting machines then slice multiple fabric layers simultaneously with millimeter accuracy—saving time while eliminating human error.

This process reflects how a professional bomber jacket manufacturer combines craftsmanship with advanced technology. The result: efficient production and exceptional precision.

Section 6: Stitching, Assembly & Detail Craftsmanship

After cutting, the individual panels are handed over to the sewing department, where the real artistry begins.

Each custom bomber jacket undergoes multiple assembly stages:

Panel Joining – Sleeves, body, and collar pieces are stitched using industrial sewing machines calibrated for accuracy.

Reinforcement – Stress points like shoulder seams, cuffs, and pockets are reinforced for durability.

Lining Installation – Soft, breathable linings are added for comfort and insulation.

Zippers & Trims – YKK or SBS zippers, ribbed cuffs, and metal snaps are attached based on client specifications.

Our skilled technicians undergo continuous training to maintain world-class sewing standards. Whether producing lightweight satin bombers or heavy-duty nylon jackets, Ginwen ensures that every piece meets design and performance expectations.

Section 7: Quality Control (QC) & Real-Time Monitoring

QC is the backbone of a reliable bomber jacket manufacturer. At Ginwen, quality control happens at every stage—not just at the end.

Inline QC: Inspectors monitor every production line for accuracy in stitching, alignment, and labeling.

Final QC: Once jackets are complete, they undergo full inspection for measurements, color consistency, and finishing.

Water and Wind Tests: For weatherproof styles, we perform hydrostatic and wind resistance checks.

Real-Time Production Monitoring: Using digital dashboards, our supervisors track bottlenecks and progress to maintain schedule accuracy.

Every custom bomber jacket leaving our facility passes through these rigorous steps before packaging.

Section 8: Packaging, Labeling & Private Branding

The final stage transforms the product into a ready-to-sell garment.

We offer a full range of private label services, including:

Branded woven or printed labels

Customized hangtags and packaging

Individual polybag or box packaging based on client preferences

Barcoded labeling for retail readiness

Whether your brand identity is minimalist or bold, we ensure that the final product aligns with your market positioning.

Each package is double-checked for order accuracy and securely packed for ex

Section 9: The Ginwen Production Advantage

As a professional bomber jacket manufacturer, Ginwen combines advanced machinery with human expertise to deliver reliable, scalable results.

Our manufacturing advantages include:

ISO 9001 & BSCI certified systems for ethical and technical assurance

CAD development & prototyping team for accuracy and flexibility

Monthly capacity of 500,000 pieces, with automated cutting, sewing, washing, printing, and packaging lines

7–14 days for sample completion and 30 days for bulk delivery

Real-time quality management to ensure every detail is under control

This integrated system allows us to serve global brands with speed, consistency, and confidence.

OEM/ODM Development: From Sampling to Bulk Orders

Section 10: Understanding OEM and ODM with a Bomber Jacket Manufacturer

In the global fashion supply chain, two terms dominate the discussion: OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing). Both describe how brands collaborate with a bomber jacket manufacturer to turn ideas into finished garments—but they serve different needs.

OEM: You Design, We Produce

In OEM projects, brands already have their own designs, sketches, or tech packs. The manufacturer follows the client’s specifications to produce custom bomber jackets that perfectly match the original concept.

At Ginwen, our OEM services include:

Reviewing tech packs and specifications for accuracy

Providing professional material sourcing advice

Translating designs into CAD patterns

Producing a sample within 7–14 days for approval

Starting bulk production (MOQ 100 pcs) within 30 days after confirmation

ODM: We Design, You Customize

ODM is ideal for brands that need creative direction or quick market entry. As a professional bomber jacket manufacturer, we offer ready-to-customize base designs that can be modified with your colors, logos, or trims.

Our ODM clients enjoy:

Faster lead times since core patterns already exist

Cost efficiency by leveraging proven silhouettes

Easy private label integration with custom tags and packaging

Both OEM and ODM paths ensure flexibility and scalability—helping brands of all sizes launch collections efficiently.

Section 11: The Sampling Stage – Precision and Collaboration

The sample phase is the most collaborative part of working with a bomber jacket manufacturer. It transforms ideas into tangible prototypes, allowing for fine-tuning before large-scale production.

Step 1: Design Consultation

Our team reviews your design intent, target audience, and preferred materials. If necessary, we suggest fabric alternatives for performance or budget optimization.

Step 2: CAD & Pattern Development

Our in-house CAD team creates detailed digital patterns and size grading to ensure precise fit consistency.

Step 3: Prototype Creation

We develop your custom bomber jacket prototype within 7–14 days, including all trims and design details. This phase allows you to evaluate quality, fit, and aesthetic appeal.

Step 4: Revision Round

After receiving feedback, we make adjustments to achieve the exact desired result. This iterative process continues until your sample is approved for mass production.

At Ginwen, we see this as a partnership rather than a transaction. Our clients appreciate that we listen closely, suggest improvements, and maintain transparency throughout the process.

Section 12: Communication & Transparency in Production

Clear communication is the cornerstone of a successful OEM/ODM relationship. Many B2B buyers encounter problems when manufacturers lack structure or responsiveness—but a professional bomber jacket manufacturer provides full visibility.

At Ginwen, we use digital project management tools to provide:

Real-time updates on production progress

Video inspections of prototypes and bulk output

Transparent cost breakdowns for materials and trims

Fast feedback loops for any design or scheduling changes

This transparency builds trust and ensures that your brand remains in control every step of the way.

Section 13: Case Studies – Successful Collaborations with Ginwen

Case Study 1: European Streetwear Brand

A mid-sized fashion label from Europe partnered with Ginwen to develop a new line of custom bomber jackets featuring reflective trims and bold embroidery. After two sampling rounds, production began, and 5,000 units were shipped in 30 days. The line sold out in under two months.

Case Study 2: North American Retail Chain

A large retailer required classic nylon bomber jackets with updated fits for its fall collection. Our OEM team worked directly with their designers to adjust silhouettes and ribbing proportions. The resulting jackets aligned perfectly with their brand DNA, earning positive reviews from buyers.

Case Study 3: Asian Workwear Distributor

This client needed heavy-duty bomber jackets for industrial uniforms. Using waterproof-coated polyester and reinforced stitching, we developed a rugged yet stylish option. With ISO 9001 & BSCI certification, Ginwen met the distributor strict safety and compliance requirements.

Each case highlights how an experienced bomber jacket manufacturer adapts to diverse market needs while maintaining high-quality standards.

Section 14: Why Brands Choose Ginwen for OEM & ODM

At Ginwen, we are not just a factory—we are your creative and production partner.

We provide:

ISO 9001 & BSCI certified production systems

Strong CAD & prototyping capability for precision

Private label customization for complete brand identity

Scalable capacity of 500,000 units per month

Real-time QC and progress tracking

Our OEM/ODM workflow is built to minimize lead times while maximizing design integrity. Whether you’re developing premium lifestyle bombers or functional outerwear, Ginwen provides the expertise to execute your vision.

Quality Control, Industry Trends & Final Takeaways

Section 15: Quality Control – The Signature of a Professional Bomber Jacket Manufacturer

Every reputable bomber jacket manufacturer knows that product quality defines long-term success. Whether producing for a luxury fashion brand or a wholesale distributor, consistency is everything.

At Ginwen, quality control (QC) and quality assurance (QA) are deeply integrated into every production stage—rather than being an afterthought. Our systems ensure that every custom bomber jacket meets international standards for performance, durability, and style.

1. Inline QC

Inspectors monitor each production line daily, checking seam alignment, zipper placement, and thread quality. Real-time correction prevents costly rework later.

2. Final Inspection

Before shipping, every batch undergoes a detailed review. We measure key dimensions, assess stitch density, and verify color matching under standardized lighting.

3. Functional Testing

For technical bombers, we conduct fabric stretch and water-repellent tests, ensuring the jackets retain both comfort and protection.

4. Packaging QC

Each jacket is checked again during packing to ensure correct labeling, barcode scanning, and logo positioning—vital for private label and retail orders.

5. Real-Time Monitoring

Through a digital production dashboard, our supervisors track bottlenecks and report updates to clients. Transparency builds confidence and ensures that every milestone is met on schedule.

This meticulous system allows Ginwen to deliver consistently high-quality custom bomber jackets, no matter the order size.

Section 16: Technology and Sustainability Trends in Bomber Jacket Manufacturing

As global apparel evolves, so does the role of the bomber jacket manufacturer. Modern buyers demand both innovation and sustainability—and factories must adapt to stay relevant.

1. Digital Production Planning

Automated cutting, 3D CAD patterning, and AI-based fabric utilization now help reduce waste and improve precision.

2. Recycled and Eco Fabrics

Recycled polyester, organic cotton, and biodegradable linings are becoming the norm. Brands increasingly choose custom bomber jackets made with eco-conscious materials that appeal to environmentally aware consumers.

3. Smart QC and Traceability

Blockchain and cloud-based systems allow full visibility from raw materials to final delivery. This data-driven transparency strengthens trust between manufacturers and global buyers.

4. Ethical Certifications

Factories that maintain ISO 9001 & BSCI certifications—like Ginwen—prove commitment not only to quality but also to responsible labor practices and sustainable operations.

5. Flexible MOQs for Modern Brands

New brands often face barriers due to large minimum orders. At Ginwen, our MOQ starts from 100 pieces, giving both startups and established labels access to premium manufacturing without overstock risk.

By blending technology, ethics, and flexibility, Ginwen leads the next generation of bomber jacket manufacturers.

Section 17: Why Partnering with Ginwen Ensures Success

When you choose Ginwen as your bomber jacket manufacturer, you’re choosing a partner that combines experience, scalability, and reliability.

We proudly offer:

ISO 9001 & BSCI certified production systems

Strong in-house CAD development and prototyping team

500,000 pcs/month capacity with automated processes (fabric inspection, washing, cutting, sewing, printing, and packaging)

Cutting, sewing, and private label services to turn your vision into reality

Real-time quality monitoring and production transparency

Sample lead time: 7–14 days | Bulk delivery: 30 days

Our mission is simple: to help brands worldwide create custom bomber jackets that combine superior craftsmanship, comfort, and style—without compromise.

Section 18: Conclusion & Call to Action

From the first sketch to the last shipment, working with a professional bomber jacket manufacturer can transform your brand’s growth potential. The process—sampling, bulk production, quality assurance, and delivery—requires discipline, experience, and seamless communication.

At Ginwen, we’ve spent over two decades refining every detail of this process. Whether you need a small production run for a capsule collection or a large-scale retail order, we’re ready to deliver.

If you’re searching for a partner that understands fashion, function, and factory efficiency, we invite you to collaborate with us.

👉 Start your project today:

Explore our Custom Bomber Jackets Collection for inspiration

Learn about our OEM & ODM Services

Contact our team directly through the Contact Us page to discuss your custom bomber jacket ideas

Let create something remarkable—together.