How to Choose a Bomber Jacket Manufacturer: 7 Key Criteria for Brands & Wholesalers

- Share

- Issue Time

- Oct 8,2025

Summary

Discover 7 key criteria to choose the right bomber jacket manufacturer and learn how Ginwen helps brands produce premium custom jackets efficiently.

Introduction: Why Choosing the Right Bomber Jacket Manufacturer Matters

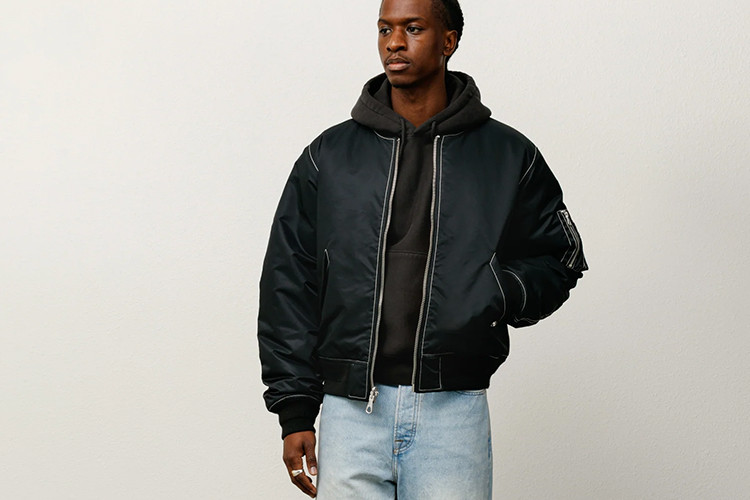

The bomber jacket has evolved from a classic military garment to a global fashion staple. Today, it a must-have piece across luxury, streetwear, and uniform lines. But behind every successful bomber jacket collection lies one crucial decision — choosing the right bomber jacket manufacturer.

For fashion brands and wholesalers, this decision defines everything from design accuracy to lead time, product quality, and profit margins. A reliable partner isn’t just a factory — it a creative and technical extension of your brand.

This guide breaks down 7 key criteria that every brand should evaluate before choosing a bomber jacket manufacturer. Whether you’re a startup creating your first custom collection or an established label scaling globally, these insights will help you make an informed and strategic choice.

Criterion 1: Certifications & Compliance

When sourcing apparel internationally, certifications are your first quality filter. They reflect a manufacturer’s commitment to global production standards, labor safety, and sustainable practices.

A professional bomber jacket manufacturer should hold certifications such as:

ISO 9001: Guarantees systematic quality management and consistent production standards.

BSCI: Confirms ethical, safe, and socially responsible working conditions.

At Ginwen, we proudly maintain both ISO 9001 & BSCI certifications, giving our clients confidence that every custom bomber jacket is produced ethically, safely, and in full compliance with international standards.

Our certified systems don’t just protect your supply chain — they strengthen your brand reputation and compliance with international buyers and retailers.

Criterion 2: In-House Development & CAD Prototyping Capabilities

Precision is everything in outerwear manufacturing. Look for a bomber jacket manufacturer that offers advanced in-house pattern-making and CAD development instead of outsourcing.

At Ginwen, our in-house CAD team transforms creative ideas into digital blueprints, ensuring flawless pattern accuracy, perfect fit, and smooth production scalability.

This stage includes:

2D/3D CAD design for technical visualization

Pattern grading for all sizes (XS–XXL or custom)

Sample adjustments before bulk production

Fit verification to ensure comfort and symmetry

Having these capabilities under one roof helps brands save time, minimize communication errors, and guarantee product consistency.

For clients requiring private label bomber jackets, our development team also assists with fabric testing, trim selection, and embroidery digitization — ensuring that design intent translates seamlessly into reality.

Why These First Two Criteria Matter

A manufacturer without certifications risks non-compliance, delayed shipments, and inconsistent results. Similarly, factories that lack CAD technology often depend on manual processes, resulting in irregular fits or slower sampling.

That why the foundation of any successful partnership with a bomber jacket manufacturer begins with two essentials: compliance and capability.

Ginwen — Your Trusted Partner for Custom Bomber Jackets

As a professional bomber jacket manufacturer, we at Ginwen combine design innovation with industrial precision. With over 20 years of experience, we specialize in OEM & ODM services for global brands — from luxury streetwear labels to uniform distributors.

We manage the full production process in-house, offering:

ISO 9001 & BSCI certified systems

In-house CAD prototyping

Monthly capacity: 500,000 pcs

Private label development (logos, trims, packaging)

MOQ from 100 pcs | Sample: 7–14 days | Bulk: 30 days

Real-time QC tracking & order transparency

Our mission is to help brands bring custom bomber jackets to market faster, smarter, and with uncompromised quality.

Production Capacity & Quality Control Systems

Criterion 3: Production Capacity & Scalability

When choosing a bomber jacket manufacturer, one of the most overlooked yet critical factors is production capacity. Brands often focus on price or samples but underestimate the importance of scalability — the ability of a manufacturer to handle both small MOQs and high-volume orders with the same level of quality and efficiency.

A reliable manufacturer should have:

Large-scale production facilities with automated workflows

Dedicated departments for cutting, sewing, printing, and packaging

Flexibility to handle small test runs as well as global wholesale orders

At Ginwen, we operate a vertically integrated factory with a monthly capacity of 500,000 pieces. This ensures that whether you’re producing 100 jackets for a capsule launch or 10,000 for a retailer, every item receives the same precision and consistency.

Our automatic production process includes:

Fabric inspection and washing

Digital pattern cutting

Industrial sewing and finishing

Logo printing or embroidery

Labeling and final packaging

This structured process allows us to deliver custom bomber jackets with shorter lead times — 7–14 days for samples and 30 days for bulk orders — while maintaining top-tier quality standards.

Why Production Capacity Matters for Brands & Wholesalers

A factory with limited capacity may struggle to meet deadlines during seasonal peaks or multi-style launches. On the other hand, a scalable bomber jacket manufacturer can seamlessly adapt to demand fluctuations without compromising delivery schedules.

At Ginwen, we understand how crucial timing is for our clients. Our automated systems and workforce coordination ensure every order runs on schedule, supported by transparent communication and real-time updates.

Criterion 4: Quality Control Systems

Even the most advanced production lines can’t succeed without a robust quality control (QC) system. For brands, quality consistency across all jackets is what defines customer satisfaction and brand credibility.

A top bomber jacket manufacturer should maintain multi-level QC processes:

1. Pre-Production Inspection

Before production begins, all materials — from zippers to ribbed cuffs — undergo testing for durability, colorfastness, and compatibility.

2. Inline Inspection

During sewing, inspectors continuously check stitch accuracy, panel alignment, and fit consistency. Early intervention prevents cumulative errors.

3. Final QC and Packaging Review

Once jackets are completed, they undergo a final inspection that covers:

Stitch density and strength

Zipper functionality

Seam symmetry

Fabric surface condition

Labeling and packaging accuracy

At Ginwen, our QC department follows strict ISO 9001 standards. Every production batch is tracked digitally through our real-time quality monitoring system, which identifies bottlenecks and ensures corrective actions immediately.

Our inspectors conduct both random sampling checks and 100% final inspections depending on the client requirements. This attention to detail has made Ginwen a trusted partner for brands that value premium quality and reliable supply.

How Ginwen QC System Supports Custom Bomber Jackets

As an experienced bomber jacket manufacturer, we recognize that every brand has its own standards — whether it’s a high-end streetwear label demanding luxury-grade fabrics or a corporate client needing uniform durability.

That why our quality assurance doesn stop at inspection; it extends to material sourcing and technical consultation.

We provide clients with performance test reports and digital photo documentation for transparency. Every custom bomber jacket is verified against your approved sample before shipment.

Additionally, we integrate client feedback loops into our QC cycle. This allows us to improve future runs continuously, ensuring long-term consistency across your collections.

Why QC Is a Competitive Advantage

Brands that partner with manufacturers lacking formal QC systems often face:

Product inconsistency across batches

High defect rates and costly returns

Reputational risk from poor quality

By contrast, a factory with integrated quality management — like Ginwen — provides peace of mind and builds sustainable partnerships based on reliability and performance.

At the end of the day, quality is not an act; it's a system. And it 's what separates a bomber jacket manufacturer from a true production partner.

Ginwen – Where Scale Meets Precision

At Ginwen, we combine industrial-scale capacity with handcrafted precision. Our production floor runs on a mix of automation and skilled labor, ensuring speed and quality go hand in hand.

We manage every step in-house — from CAD prototyping and fabric cutting to labeling and shipment — allowing brands and wholesalers to launch collections quickly and confidently.

Whether you’re building your next custom bomber jacket line or sourcing for large wholesale contracts, Ginwen manufacturing ecosystem guarantees the performance and consistency your brand deserves.

Private Label Services & Transparent Communication

Criterion 5: Private Label & Customization Capabilities

One of the main reasons brands work with a bomber jacket manufacturer instead of a trading company is to gain full creative control over customization. Whether you’re building a retail-ready fashion collection or designing a functional uniform line, private label flexibility is what makes your product distinct in a crowded market.

A professional manufacturer should provide full OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) capabilities, ensuring you can personalize every detail of your custom bomber jackets.

What Private Label Means for Your Brand

Private label services go beyond simple logo placement. They allow brands to:

Develop custom patterns and fits that align with brand DNA

Choose from diverse fabrics such as nylon, cotton, twill, or polyester blends

Add bespoke trims — zippers, ribbed cuffs, buttons, linings, or embroidery

Customize logos, woven labels, and packaging for retail presentation

Control colorways and finishing techniques (matte, glossy, or coated looks)

Ginwen Private Label Expertise

At Ginwen, we specialize in transforming creative designs into production-ready garments. As a seasoned bomber jacket manufacturer, we work with global brands that require different levels of customization — from high-end streetwear aesthetics to corporate branding uniforms.

Our OEM & ODM services include:

Pattern development using CAD software for precision

Fabric testing and sampling

Logo embroidery and print customization

Private label trims, hangtags, and sustainable packaging

Digital mockups for brand presentation approval

We take pride in offering a one-stop service — from pattern-making to packaging — ensuring your private label bomber jackets not only look distinctive but also reflect professional craftsmanship.

📍 Explore our services here:

Why Private Labeling Is a Game-Changer

In today competitive apparel market, differentiation is vital. Private label customization helps you:

Build brand identity and exclusivity

Improve profit margins by avoiding middlemen

Respond faster to market trends and seasonal changes

Enhance consumer loyalty with signature details and consistency

Whether you’re a wholesaler launching your own label or a retailer looking for brand-specific outerwear, working with a flexible bomber jacket manufacturer like Ginwen gives you full design freedom while maintaining production reliability.

Criterion 6: Communication, Transparency & Partnership

Even with modern machinery, the success of every manufacturing project still depends on one thing — clear communication. A reliable bomber jacket manufacturer must maintain open, proactive, and transparent dialogue from the first inquiry to final delivery.

What Transparency Looks Like in Practice

Detailed Quotations: Every cost component — fabric, trims, and labor — should be clearly itemized.

Real-Time Order Tracking: Updates on sampling, cutting, sewing, and shipment stages through digital dashboards or regular reports.

Fast Response Times: Efficient handling of revisions or feedback ensures deadlines are never compromised.

Visual Progress Updates: Photos or videos during sampling and production provide reassurance for international clients.

At Ginwen, we operate under a philosophy of “no surprises, only solutions.” We understand how crucial visibility is for overseas buyers, especially for fashion brands managing multiple collections simultaneously.

We use digital monitoring tools to track every order progress — from fabric arrival to packaging — ensuring complete transparency. Clients receive updates at every milestone, so they know exactly when their custom bomber jackets are entering each stage of production.

Building Long-Term Partnerships

Reliable communication goes hand-in-hand with trust. We believe that successful partnerships aren’t just about one-time transactions but about long-term growth and mutual success.

Our clients — from emerging designers to global wholesalers — choose Ginwen because we act as their extended production team. We offer advice on fabric optimization, technical adjustments, and sustainable alternatives, ensuring their products meet both quality and market standards.

This level of collaboration has helped Ginwen become a preferred bomber jacket manufacturer for clients across Europe, North America, and Asia.

Ginwen – Your Trusted Partner in Custom Bomber Jackets

With 20+ years of manufacturing experience, Ginwen delivers the perfect balance of creativity, technology, and reliability.

ISO 9001 & BSCI certified systems

CAD pattern development and 3D prototyping

500,000 pcs monthly capacity

7–14 day sample timeline, 30-day bulk delivery

Private label service with brand customization options

Real-time communication and progress tracking

For brands and wholesalers seeking a dependable bomber jacket manufacturer, Ginwen is the partner that helps you move from design concept to global retail success.

Criterion 7: Lead Time & Reliability

In fashion manufacturing, time is money — and delays can mean missed seasons, lost opportunities, and frustrated clients. When choosing a bomber jacket manufacturer, always evaluate their track record on lead times, reliability, and communication.

Why Lead Time Matters

A manufacturer’s ability to meet deadlines determines your supply chain efficiency. Fast sampling and timely delivery give your brand the agility to launch new styles, restock hot sellers, and respond to seasonal demand.

Professional factories balance speed and quality through organized production lines and experienced management. But a great bomber jacket manufacturer goes further — integrating real-time tracking and predictive scheduling to avoid bottlenecks.

At Ginwen, we’ve built a workflow designed for speed without compromise.

Sample timeline: 7–14 days

Bulk production: 30 days

MOQ: 100 pieces

Monthly capacity: 500,000 pieces

This balance between flexibility and scale allows us to support brands of all sizes, from boutique labels to global wholesalers.

Our real-time monitoring system ensures that every order is traceable, every deadline visible, and every milestone communicated proactively. Clients receive weekly progress reports and photos from the factory floor, eliminating uncertainty and keeping production on track.

Why Reliability Is the True Test of a Manufacturer

While pricing and design capabilities often attract clients initially, reliability is what keeps them returning. A dependable bomber jacket manufacturer consistently delivers:

1.Accurate samples that match production

2.Quality control reports before shipment

3.Transparent communication about any timeline adjustments

4.Consistent adherence to ethical and compliance standards

At Ginwen, reliability isn’t a promise — it’s a measurable process. Our factory managers track daily production progress, and our client support team ensures that every message or question is addressed within 24 hours.

This systematic reliability has helped us earn long-term partnerships with brands across Europe, North America, and Asia.

Recap: 7 Key Criteria for Choosing a Bomber Jacket Manufacturer

When evaluating suppliers, brands and wholesalers should always measure potential partners against these seven essential standards:

1.Certifications & Compliance – Ensure ISO 9001 and BSCI certifications.

2.In-House Development & CAD Prototyping – Guarantees design precision and fit accuracy.

3.Production Capacity & Scalability – Look for factories that can handle both small and large orders.

4.Quality Control Systems – Check for multi-stage QC aligned with international standards.

5.Private Label Services – Seek OEM/ODM flexibility to create unique products.

6.Communication & Transparency – Expect clear, proactive, and real-time updates.

7.Lead Time & Reliability – Choose a partner who delivers on time, every time.

If your potential supplier checks all these boxes, you’ve found more than a factory — you’ve found a partner that can help your brand grow sustainably.

Why Ginwen Meets All 7 Criteria

At Ginwen, we pride ourselves on being a bomber jacket manufacturer that fully meets — and exceeds — these seven standards.

Our Core Strengths:

ISO 9001 & BSCI certified manufacturing systems

Strong in-house CAD development and prototyping

500,000 pcs/month capacity with automated processes (fabric inspection, cutting, sewing, printing, packaging)

Comprehensive OEM & ODM support for private label clients

Real-time QC and production tracking

7–14 days for samples / 30 days for bulk

MOQ starting from 100 pcs

We’re more than a factory — we’re a global partner for brands that value consistency, speed, and craftsmanship. Our OEM & ODM services empower clients to launch collections confidently, knowing every custom bomber jacket is made to the highest international standard.

Conclusion: Your Next Step Toward the Right Partnership

Choosing a bomber jacket manufacturer is one of the most strategic decisions a fashion brand or wholesaler can make. The right partner saves you time, enhances your brand reputation, and ensures product success season after season.

At Ginwen, we make this decision easy. With over two decades of manufacturing experience, certified systems, and advanced technology, we help clients bring ideas to life — efficiently and reliably.

Whether you need lightweight nylon bombers for your streetwear line or insulated varsity-inspired styles for your winter collection, we’ve got you covered.

👉 Start your project today:

Explore our Custom Bomber Jackets Collection for design inspiration

Learn more about our OEM & ODM Service options

Reach out directly through our Contact Us page — our team will respond within 24 hours

Let create your next successful custom bomber jacket collection — from design to delivery.