How to Choose a Waterproof Jackets Manufacturer: Materials, Tests, and MOQ

- Share

- Issue Time

- Oct 9,2025

Summary

Learn how to choose a reliable Waterproof Jackets Manufacturer with insights on materials, testing, MOQ, and why Ginwen is your best OEM & ODM partner.

Introduction: The Global Demand for Quality Waterproof Jackets

From outdoor exploration to urban commuting, waterproof jackets have become an essential category in global apparel markets. They are no longer limited to mountaineers or athletes — today consumers expect both style and functionality in their outerwear.

For fashion brands and wholesalers, this rising demand creates an incredible opportunity. But success depends on one critical decision: choosing the right Waterproof Jackets Manufacturer.

A professional manufacturer not only produces garments but also safeguards your brand reputation. The right partner ensures waterproof performance, consistent quality, reliable delivery, and long-term scalability. In contrast, choosing the wrong one could mean delayed shipments, product failures, or even lost customers.

This guide will show you how to evaluate a Waterproof Jackets Manufacturer, focusing on materials, performance tests, and MOQ (Minimum Order Quantity) — the three factors that define production success.

Why the Right Waterproof Jackets Manufacturer Matters

A great factory does more than sew seams — it combines technical expertise, certified systems, and design precision. Waterproof jackets involve complex engineering, including:

1.Hydrostatic pressure testing

2.Seam sealing and bonding

3.Breathability control

4.Coating or membrane layering

Only manufacturers with the right experience and certification can manage this complexity. When evaluating potential suppliers, ask yourself:

1.Do they understand waterproof performance beyond marketing terms?

2.Can they translate your brand’s designs into technical patterns?

3.Are they ISO-certified and ethically compliant?

4.Can they handle both small test runs and large wholesale volumes?

At Ginwen, we answer “yes” to all of these questions. As a professional Waterproof Jackets Manufacturer with over 20 years of experience, we support brands worldwide with OEM & ODM production services, from fabric sourcing to final shipment.

Section 1: What Makes a Reliable Waterproof Jackets Manufacturer

When comparing suppliers, look for manufacturers that demonstrate:

ISO 9001 & BSCI certified systems, ensuring ethical and quality compliance.

In-house CAD patterning and prototyping for technical accuracy.

Large-scale capacity (at least 200,000–500,000 pcs/month) to ensure scalability.

Full-service OEM & ODM support, including private label customization.

Real-time QC and production transparency to reduce risk.

These aren’t “extras” — they are non-negotiable essentials in today’s apparel industry.

At Ginwen, our production facility integrates automation with craftsmanship. We inspect fabrics before cutting, use high-frequency seam-sealing machines, and monitor progress digitally throughout production. This ensures that every custom waterproof jacket meets your expectations — functionally and aesthetically.

Section 2: Our Manufacturing Process Overview

To help clients understand how we work, here’s how production typically flows at Ginwen:

1.Consultation & Design Review – We study your tech pack or sketches, providing material recommendations.

2.Sampling (7–14 days) – Our CAD team develops prototypes for testing and fitting.

3.Material Testing & Approval – We test fabrics for waterproofing, breathability, and durability.

4.Bulk Production (30 days) – Once approved, the order moves into automated mass production.

5.Quality Control & Final Inspection – Our QC team ensures every piece meets international standards.

6.Packaging & Shipping – Each item is labeled, packed, and tracked for export.

With a monthly capacity of 500,000 pieces, we can handle seasonal fluctuations and urgent lead times while maintaining consistent quality.

Section 3: Ginwen – Your Reliable Waterproof Jackets Manufacturer

At Ginwen, we manufacture custom waterproof jackets for outdoor, fashion, and lifestyle brands. Our products combine durability with design flexibility, supported by:

ISO 9001 & BSCI certified systems

In-house CAD prototyping

500,000 pcs/month automated capacity

Private label OEM & ODM customization

Real-time quality monitoring

MOQ from 100 pcs

7–14 day sample, 30-day bulk turnaround

Our mission is to make premium waterproof apparel accessible to brands of all sizes — from boutique designers to international retailers.

Waterproof Materials & Fabric Technologies Explained

Understanding Waterproof Materials

When choosing a Waterproof Jackets Manufacturer, the first factor to evaluate is material technology. A jacket’s performance depends largely on the fabrics and membranes used to keep moisture out while allowing breathability.

A professional manufacturer understands not just sewing but also the science of waterproofing — knowing how fabrics behave under pressure, humidity, and movement.

The most common waterproof materials used in custom waterproof jackets include:

1. Nylon with PU Coating

Polyurethane-coated nylon is lightweight, affordable, and ideal for fashion or light outdoor jackets. It provides basic water resistance with a hydrostatic head rating of 5,000–10,000 mm H₂O.

2. Polyester with TPU or PU Membrane

Polyester fabrics with laminated membranes offer stronger waterproofing and durability, suitable for sportswear and hiking jackets. They often achieve ratings between 10,000–20,000 mm H₂O.

3. 3-Layer Laminated Fabrics (e.g., Nylon + Membrane + Lining)

High-end outdoor collections often use 3-layer constructions that combine a durable face fabric, waterproof-breathable membrane, and inner lining. These fabrics provide superior water resistance and breathability, comparable to branded materials like GORE-TEX®.

4. Recycled and Sustainable Waterproof Fabrics

As sustainability becomes a major priority, many brands now demand eco-conscious materials such as recycled polyester or organic cotton with PFC-free coatings. A skilled Waterproof Jackets Manufacturer should offer these options while maintaining performance integrity.

At Ginwen, we source from verified mills that provide OEKO-TEX®-certified fabrics and recyclable membranes, helping brands align with modern environmental standards.

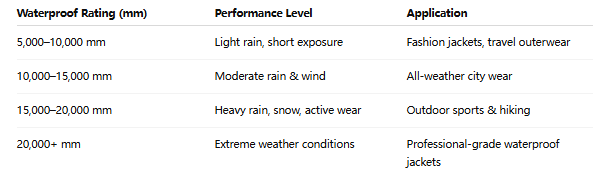

Waterproof Ratings: What They Really Mean

A jacket waterproof level is measured using the Hydrostatic Head Test, which determines how much water pressure the fabric can resist before leaking.

When selecting a Waterproof Jackets Manufacturer, brands should verify that their supplier conducts these tests regularly and maintains laboratory data for each fabric batch.

At Ginwen, we test every fabric for hydrostatic pressure, breathability (g/m²/24hr), and tear strength before production. This ensures that our custom waterproof jackets perform reliably across climates and activities.

Breathability & Comfort: The Balancing Act

True waterproof jackets are not only about blocking water — they also need to let heat and moisture escape. This is measured through MVTR (Moisture Vapor Transmission Rate).

A fabric with a rating of 5,000–10,000 g/m²/24hr is suitable for casual wear, while 15,000–25,000 g/m²/24hr supports high-intensity outdoor activities.

As an experienced Waterproof Jackets Manufacturer, Ginwen balances waterproofing with breathability through advanced lamination and seam-sealing techniques. Our jackets maintain dry comfort even under demanding conditions.

We also use taped seams and YKK or SBS waterproof zippers to eliminate leakage points — small details that significantly impact performance.

Additional Fabric Treatments

Besides coatings and membranes, several treatments enhance a jacket functionality and appearance:

DWR (Durable Water Repellent): A surface treatment causing water to bead off easily.

Anti-wrinkle finish: Keeps fabric smooth and stylish for fashion applications.

UV protection coating: Adds sun resistance for outdoor adventures.

Reinforced panels: Extra durability on shoulders and elbows for active use.

At Ginwen, we integrate these finishing technologies into our OEM & ODM production lines based on brand requirements — from minimalist fashion bombers to heavy-duty mountaineering shells.

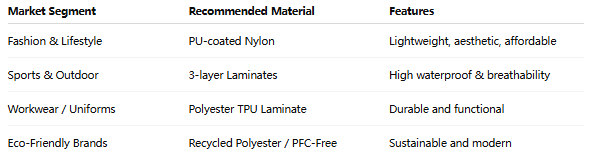

Choosing the Right Fabric for Your Brand

When collaborating with a Waterproof Jackets Manufacturer, your material choice should align with your brand target audience and purpose.

Our team at Ginwen helps clients select fabrics that match their brand goals, budget, and performance needs. Through our OEM & ODM waterproof jackets service, we provide technical consultation, fabric sourcing, and sample validation to ensure the chosen materials deliver both function and style.

Learn more about our full customization capabilities here:

Ginwen Material Strengths

As a trusted Waterproof Jackets Manufacturer, we prioritize material quality, sustainability, and innovation.

All fabrics are pre-tested for hydrostatic pressure and breathability.

We maintain long-term partnerships with certified mills.

Every project includes a full material data sheet for transparency.

This guarantees that our clients receive not just waterproof jackets, but technically engineered garments designed to last.

Waterproof Tests, QC, and MOQ: How Manufacturers Ensure Quality and Efficiency

The Role of Testing in Waterproof Jacket Production

A true Waterproof Jackets Manufacturer goes far beyond cutting and sewing — it’s about engineering performance. Testing ensures every product can withstand real-world conditions such as heavy rain, wind, and humidity without failure.

At Ginwen, we integrate testing throughout the entire production process to guarantee durability and consistency for our custom waterproof jackets.

1. Hydrostatic Head Test

This test measures the fabric water resistance by determining how much pressure it can handle before leaking. Each fabric batch used in Ginwen’s production is tested to meet a minimum rating of 10,000–20,000 mm H₂O, depending on client requirements.

2. Seam Sealing and Adhesion Test

Even if the fabric is waterproof, poorly sealed seams can cause leaks. We test seam tape adhesion strength and ensure bonding durability through high-frequency heat-sealing technology.

3. Zipper Waterproof Test

Zippers are common failure points. Ginwen uses YKK or SBS waterproof zippers and performs submersion tests to ensure water-tight performance under movement.

4. Breathability (MVTR) Test

A jacket must block rain yet release heat and moisture. Using standardized Moisture Vapor Transmission Rate tests, we verify breathability levels of 5,000–25,000 g/m²/24h, suitable for both daily wear and professional sports applications.

5. Field Testing

Beyond the lab, our QA team conducts real-condition wear tests — simulating rain and motion to assess comfort, flexibility, and seam reliability.

These testing protocols are critical for any brand seeking to collaborate with a reliable Waterproof Jackets Manufacturer. They ensure the finished product not only meets technical specs but also delivers customer satisfaction.

Quality Control (QC) Systems: From Fabric to Final Packing

Quality control determines whether a manufacturer can consistently meet your brand’s standards.

At Ginwen, we apply a multi-stage QC framework that begins even before production starts.

Pre-Production QC

Inspect incoming fabrics for color consistency, coating quality, and hydrostatic performance.

Approve trims and zippers based on brand specifications.

Validate patterns using CAD fitting simulations.

Inline QC

Dedicated inspectors monitor sewing lines for precision in stitching, seam sealing, and trimming.

Any deviation is corrected immediately to prevent downstream defects.

Final QC

Each custom waterproof jacket undergoes a comprehensive inspection covering:

Seam sealing integrity

Zipper functionality

Fabric surface and color

Fit and measurement tolerance

Label and packaging accuracy

Every piece leaving Ginwen’s facility is verified against AQL (Acceptable Quality Limit) standards and accompanied by inspection reports for brand documentation.

Real-Time Monitoring

To further enhance transparency, our digital management system tracks production progress in real time — from cutting to final inspection. This enables clients to receive accurate updates without delays or communication gaps.

Understanding MOQ: Why It Matters

MOQ — Minimum Order Quantity — is one of the most practical factors brands should consider when choosing a Waterproof Jackets Manufacturer.

It defines how accessible and flexible your production partnership will be.

Why MOQ Is Important for Brands

Startups & Emerging Brands: Lower MOQs allow smaller runs for testing markets or capsule collections.

Wholesalers & Retail Chains: Higher MOQs enable cost efficiency and faster replenishment cycles.

Private Label Projects: Flexible MOQs let brands test new designs without overcommitting inventory.

At Ginwen, our MOQ starts at 100 pieces, making professional manufacturing accessible for both small and large clients. Whether you need 100 samples or 10,000 bulk pieces, our automated systems adapt production volumes without compromising quality.

Lead Times and Production Efficiency

For global buyers, time is often as important as quality. A professional Waterproof Jackets Manufacturer must deliver both.

At Ginwen, we achieve rapid turnaround through an optimized, automated workflow:

Sample production: 7–14 days

Bulk order completion: 30 days after sample approval

Monthly capacity: 500,000 pieces

Our lean manufacturing structure minimizes idle time and ensures reliable delivery — even during peak seasons. Combined with ISO 9001 & BSCI certified systems, it allows brands to maintain steady supply chains and predictable schedules.

OEM & ODM Flexibility

Ginwen production model is designed for flexibility. As an OEM & ODM Waterproof Jackets Manufacturer, we offer two cooperation modes:

OEM: You provide the design, we execute production with exact precision.

ODM: We assist in design and material development, customizing styles under your private label.

This dual approach helps brands of all sizes — from new startups to established wholesalers — to expand their waterproof outerwear collections effortlessly.

Learn more about our OEM & ODM customization process:

Ginwen Quality & Efficiency Promise

We believe reliability isn’t just about meeting deadlines — it about delivering consistent excellence. Every custom waterproof jacket produced by Ginwen represents our commitment to quality, efficiency, and transparency.

Our clients trust us because we integrate testing, real-time QC, and responsible MOQ management into a single, seamless production ecosystem.

Why Choosing the Right Manufacturer Defines Your Brand

In the world of outerwear manufacturing, selecting the right Waterproof Jackets Manufacturer determines whether your brand stands out or fades into the crowd.

A great factory doesn’t just produce garments — it becomes a trusted partner who understands your brand DNA, meets strict deadlines, and delivers consistent quality season after season.

The key lies in three pillars: material integrity, testing excellence, and efficient production.

And this is exactly what Ginwen stands for.

1. Our Certification & Compliance

At Ginwen, we understand that credibility starts with compliance.

Our facilities are ISO 9001 & BSCI certified, ensuring international quality management and ethical manufacturing standards.

This means that every custom waterproof jacket we produce aligns with strict performance and safety requirements, from raw material inspection to shipment.

ISO 9001 Certified for Quality Management

BSCI Certified for Social Responsibility

OEKO-TEX® and RDS-approved fabric sourcing partners

These certifications are not just badges — they are part of our identity as a responsible Waterproof Jackets Manufacturer.

2. Advanced Production Capability

With over 20 years of experience in outerwear production, Ginwen combines craftsmanship with technology.

Our factory operates an automated production system that handles every stage of jacket manufacturing under one roof:

Fabric inspection and washing

Cutting, printing, and embroidery

Seam sealing and waterproof testing

Stitching, finishing, and packaging

Our monthly production capacity reaches 500,000 pieces, giving us the flexibility to manage small orders and large wholesale projects simultaneously.

3. Professional OEM & ODM Service

As an experienced OEM & ODM Waterproof Jackets Manufacturer, we help brands transform design ideas into reality.

Our services include:

CAD pattern development & prototyping for accurate fit

Fabric selection & lab testing based on waterproof rating requirements

Private label customization (logos, trims, hangtags, and packaging)

Digital mock-ups & pre-production samples

Real-time production tracking and feedback

Every collaboration begins with a detailed consultation — we listen, plan, and execute precisely.

📍 Explore our customization capabilities here:

4. Quality Control You Can Trust

Quality is the foundation of our reputation.

Our integrated QC system covers four key stages:

Material Testing – hydrostatic head, breathability, and coating adhesion

Inline QC – seam sealing, measurement accuracy, and stitching precision

Final Inspection – AQL-based inspection before shipment

Digital Reporting – transparent documentation shared with clients

We also maintain real-time progress tracking — so brands can monitor production, approve samples, and stay informed every step of the way.

This attention to detail ensures that every custom waterproof jacket leaving our facility meets both technical performance and brand aesthetic expectations.

5. Fast Lead Time & Reasonable MOQ

We understand that flexibility is critical, especially for new brands or seasonal projects.

That’s why we maintain:

Sample time: 7–14 days

Bulk production: 30 days after approval

MOQ: 100 pieces

This balance between speed and scalability enables both startups and established brands to work efficiently with a reliable Waterproof Jackets Manufacturer.

6. Why Brands Choose Ginwen

Global fashion and outdoor brands choose Ginwen because we provide not only manufacturing strength but also partnership reliability.

Our clients value our:

ISO-certified process integrity

Efficient turnaround and transparency

OEM & ODM flexibility for creative designs

Private label expertise for branding growth

Scalable production for bulk or capsule collections

Consistent QC and performance testing

📍 See our product range:

7. Sustainable & Ethical Manufacturing

Modern consumers expect sustainability — and we make it part of our core.

Our fabrics include recycled polyester, PFC-free coatings, and OEKO-TEX® certified textiles.

We continuously invest in cleaner technologies and waste-reduction systems, ensuring that our waterproof outerwear meets both performance and environmental standards.

This commitment makes Ginwen not just a Waterproof Jackets Manufacturer, but a long-term sustainable partner for forward-thinking fashion brands.

Conclusion: Your Next Step

Choosing the right Waterproof Jackets Manufacturer is a strategic decision that impacts your brand’s quality, cost, and reputation.

At Ginwen, we make that choice simple.

With 20 years of experience, ISO & BSCI certification, full in-house production, and rapid delivery cycles, we provide a complete manufacturing ecosystem designed to empower global brands.

Whether you’re launching your first outdoor collection or expanding your wholesale portfolio, we’re here to support your vision — from sketch to shipment.

👉 Let’s create your next waterproof jacket line together.

Start today by:

1.Exploring our Custom Waterproof Jackets Collection

2.Reviewing our OEM & ODM Service

3.Contacting us directly via Contact Us for quotations or sample requests.

We’ll reply within 24 hours — ready to help you bring your design to life.