OEM & ODM Waterproof Jacket Manufacturer for Brands & Retailers

- Share

- Issue Time

- Sep 25,2025

Summary

Looking for a trusted OEM & ODM Waterproof Jacket Manufacturer? Ginwen offers low MOQ from 1pieces, ISO & BSCI certified,500,000 pieces/month capacity, and custom down filling jackets globally.

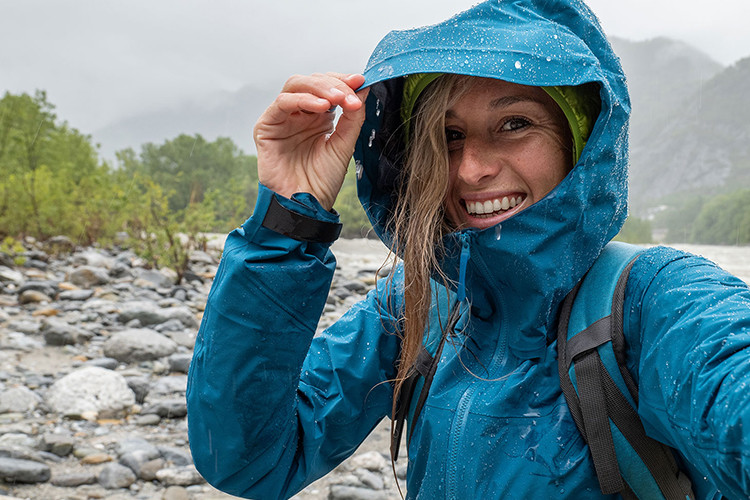

Introduction: Why Waterproof Jackets Are a Strategic Product for Brands

In today fashion and outdoor markets, waterproof jackets are no longer optional—they are a necessity. From luxury fashion houses to outdoor sportswear retailers, waterproof jackets represent a product category that balances function, style, and sustainability. For brands and wholesalers, choosing the right waterproof jacket manufacturer can make the difference between a successful product launch and a costly failure.

The global waterproof outerwear industry is rapidly evolving, shaped by consumer demand for performance fabrics, eco-conscious materials, and innovative designs. Beyond protection against rain and wind, modern waterproof jackets must integrate breathability, lightweight insulation such as down filling, and private label customization to meet the needs of diverse audiences—from urban commuters to mountaineers.

This is where an experienced OEM & ODM waterproof jacket manufacturer comes into play. As brands expand collections, finding a partner with proven expertise in fabric technology, CAD prototyping, ISO-certified production, and high-capacity supply chains is essential.

OEM & ODM Manufacturing: The Backbone of Brand Success

OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services allow fashion labels and outdoor retailers to expand product lines without building in-house factories.

OEM Waterproof Jackets: The brand provides the design, and the manufacturer handles production at scale.

ODM Waterproof Jackets: The manufacturer develops new designs, offers prototyping, and allows brands to private label these styles as their own.

For brands targeting fast seasonal launches or capsule collections, ODM accelerates the go-to-market process. For labels that prioritize brand identity and design exclusivity, OEM ensures that every technical element—from down filling insulation to waterproof membrane layering—is executed with precision.

At the core of both services lies the manufacturer’s ability to adapt, innovate, and deliver with consistency. That why choosing a factory with ISO 9001 & BSCI certification, automated quality management, and scalable production systems is critical.

Ginwen – Your Reliable Partner in Custom Waterproof Jackets

At Ginwen, we specialize in custom waterproof jacket manufacturing for global brands, retailers, and wholesalers. With 20+ years of experience in outerwear, we have earned a reputation for precision, innovation, and ethical production standards.

Unlike many manufacturers that impose high minimum orders, we proudly offer a low MOQ of just 1 piece, making us the ideal partner for:

Startups testing new collections

Established brands developing samples

Retailers planning capsule or seasonal product launches

But low MOQ does not mean compromise. Our factory delivers monthly production capacity of 500,000 units, powered by automated systems for fabric inspection, washing, cutting, sewing, and packaging. This scale allows us to support both small-batch custom designs and large-volume wholesale orders without delays.

Our factory holds ISO 9001 & BSCI certification, ensuring compliance with global quality and ethical manufacturing standards. From CAD prototyping and waterproof seam sealing to down filling integration for warmth, we provide full in-house solutions that reduce outsourcing risks.

Why Choose Us:

ISO 9001 & BSCI certified production systems

MOQ from 1 piece (perfect for startups & samples)

500,000 pieces/month capacity with automated processes

CAD development & prototyping support

Private label expertise: logos, trims, labels, and packaging

Full in-house facilities: washing, cutting, sewing, printing, QC

Real-time quality and progress monitoring

The Importance of Material Innovation in Waterproof Jackets

Waterproof jackets are not defined only by outer fabric coatings. Instead, true performance depends on multi-layered construction:

Outer Shell: Durable water-repellent (DWR) fabric that resists rain and wind.

Membrane Layer: High-performance films (like PU or PTFE) ensuring waterproofness and breathability.

Insulation Layer: Often includes down filling or synthetic alternatives, ensuring thermal efficiency.

Inner Lining: Designed for comfort and moisture management.

By controlling every step in the process, manufacturers like Ginwen ensure that waterproof jackets remain lightweight yet insulated, breathable yet durable, and always aligned with customer design requirements.

For brands seeking differentiation, materials also provide opportunities for sustainable storytelling. Incorporating eco-friendly fabrics, recycled linings, and RDS-certified down filling not only enhances jacket performance but also strengthens a brand’s sustainability narrative.

Lead Times: From Sampling to Bulk Production

One of the key challenges in fashion manufacturing is balancing speed with quality. At Ginwen, we guarantee competitive lead times without sacrificing standards:

Sample Development: 7–14 days

Bulk Production: Approx. 30 days

Our real-time progress tracking system provides transparency for clients. Whether you are developing a custom waterproof parka with down filling or a lightweight packable rain shell, we ensure deadlines are met and expectations exceeded.

Advanced Customization for Private Label Waterproof Jackets

In today competitive marketplace, brands need more than just a functional waterproof jacket—they need a product that reflects their unique identity. That why advanced customization and private labeling are essential components of OEM & ODM manufacturing.

At Ginwen, we understand that every client has a distinct brand voice and market positioning. We offer a comprehensive range of private label services, ensuring that your waterproof jackets are tailored to match your vision. These services include:

Custom Logos & Branding: Embroideries, heat-transfer logos, screen printing, silicone labels.

Trims & Accessories: Custom zippers, waterproof pockets, branded snap buttons, reflective tapes.

Packaging Solutions: Hang tags, swing tickets, retail-ready packaging with your brand’s visual language.

Fabric & Color Options: From muted tones to vibrant palettes, from eco-friendly coatings to premium down filling insulation options.

This approach transforms a standard waterproof jacket into a product that communicates your brand’s quality, sustainability, and performance values. Whether you are a premium fashion label or a sportswear retailer, our OEM & ODM solutions make it easy to stand out in a crowded market.

Technical Features that Define High-Performance Jackets

Waterproof jackets are judged not only by style but also by technical performance. Retailers and wholesalers rely on manufacturers who can deliver advanced features that elevate customer satisfaction and ensure long-lasting use.

Some of the technical features Ginwen provides include:

1.Waterproof Seams

Seam-sealed construction ensures no water leakage through stitching, a critical feature for true waterproof performance.

2.Breathable Membranes

Jackets combine waterproofness with breathability, allowing moisture to escape while blocking external rain.

3.Down Filling & Thermal Insulation

For colder climates, we integrate down filling or synthetic insulation to provide warmth without excess weight. Our sourcing includes RDS-certified down, giving your brand an eco-friendly story to share with customers.

4.Durable Water Repellency (DWR) Coatings

Advanced coatings protect the outer shell, extending product life and maintaining appearance after multiple washes.

5.Lightweight Packability

Compact designs for outdoor brands targeting travelers and hikers.

6.Eco-Friendly Options

Recycled fabrics, water-based coatings, and organic linings are available for brands prioritizing sustainability.

By integrating these features, we ensure that your custom waterproof jackets are market-ready, satisfying both technical demands and customer expectations.

Case Study: Supporting a Start-Up Outdoor Brand

To illustrate how Ginwen supports brands, let consider a real-world scenario.

A European outdoor start-up approached us with the challenge of launching a capsule collection of waterproof jackets with down filling insulation. They needed low MOQ production, rapid prototyping, and eco-conscious fabrics.

Our solution included:

Developing CAD prototypes of three jacket styles within 10 days.

Providing samples in 14 days, complete with private label logos and trims.

Sourcing recycled polyester shells and RDS-certified down filling.

Completing bulk production of 500 units within 30 days.

The result was a successful launch that attracted wholesale buyers, expanded their distribution channels, and built credibility in the European outdoor apparel market. This demonstrates how low MOQ from 1 piece allows small brands to test the market while still enjoying enterprise-level manufacturing support.

How Retailers Benefit from Partnering with a Trusted Manufacturer

For retailers and wholesalers, working with a reliable waterproof jacket manufacturer like Ginwen provides multiple benefits:

1.Consistency Across Collections

With a production capacity of 500,000 pieces per month, we maintain consistency across large wholesale orders and repeat productions.

2.Faster Time to Market

Our sample lead time of 7–14 days and bulk lead time of 30 days mean you can align with seasonal trends without delays.

3.Scalability for Growth

Whether you start with MOQ 1 piece or scale up to thousands, our automated facilities adapt to your growth.

4.Risk Reduction

In-house CAD development, fabric inspection, cutting, sewing, and packaging ensure full control of quality—reducing the risks of outsourcing.

5.Sustainability Edge

Offering eco-friendly fabrics and down filling options positions your brand as part of the global sustainability movement, resonating with modern consumers.

6.Cost Efficiency

Partnering with a manufacturer that manages the full process in-house cuts unnecessary middlemen costs and ensures competitive pricing.

Ginwen OEM & ODM Services

As a trusted OEM & ODM waterproof jacket manufacturer, we provide end-to-end solutions:

Design & Prototyping: CAD-based design support for new concepts.

Sampling: Quick development of accurate samples within 7–14 days.

Production: Scalable automated manufacturing capacity for small and large orders.

Private Labeling: Custom branding, trims, and packaging tailored to your brand.

Quality Control: Real-time tracking and bottleneck management to ensure timely delivery.

Whether you are a start-up fashion brand, mid-size retailer, or global distributor, our services are designed to meet your needs while ensuring efficiency, quality, and reliability.

Global Market Trends in Waterproof Jackets

The demand for waterproof jackets continues to grow across multiple consumer segments, from high-fashion to outdoor performance apparel. According to industry research, the waterproof outerwear market is projected to increase steadily over the next decade, driven by three major trends:

1.Performance & Lifestyle Convergence

Consumers expect waterproof jackets to provide both technical performance and fashionable aesthetics. This shift creates opportunities for brands that can deliver stylish silhouettes without compromising on function.

2.Rise of Sustainable Materials

Eco-conscious consumers increasingly demand jackets made with recycled fabrics, water-based coatings, and responsibly sourced down filling. Brands that fail to adapt risk losing market share to competitors with stronger sustainability narratives.

3.Customization & Private Labeling

Retailers seek distinctive designs to differentiate themselves in saturated markets. This has fueled demand for OEM & ODM waterproof jacket manufacturers capable of supporting private label programs with flexible MOQs.

By aligning with these trends, brands can secure stronger consumer loyalty and open new sales channels.

Sustainability & Material Innovation

Sustainability is no longer a niche—it the new standard. For waterproof jackets, this means rethinking not only the outer shell materials but also the insulation layers and production processes.

At Ginwen, we are actively developing sustainable solutions that don’t compromise on performance:

Recycled Polyester Shells: Reduces environmental impact while maintaining durability.

Water-Based DWR Coatings: Minimizes harmful chemicals in fabric finishing.

RDS-Certified Down Filling: Guarantees ethical sourcing of down insulation, meeting global retail requirements.

Eco-Friendly Packaging: Options include recyclable garment bags and biodegradable hang tags.

These innovations allow our clients to meet both regulatory requirements and consumer expectations. As more retailers demand transparent supply chains, partnering with a manufacturer that integrates sustainability at every stage becomes a strategic advantage.

Why Ginwen Leads as a Waterproof Jacket Manufacturer

At Ginwen, we position ourselves as more than just a factory—we are a long-term partner to fashion brands, outdoor labels, and global retailers. Our strengths include:

1.ISO 9001 & BSCI Certified Systems

Guaranteeing both quality and ethical standards across all processes.

2.Low MOQ from 1 Piece

Ideal for start-ups, sample development, and capsule collections.

3.Massive Production Capacity

With a monthly capacity of 500,000 units, we scale effortlessly from small-batch production to wholesale orders.

4.In-House CAD & Prototyping

Supporting rapid design development and accurate sample creation.

5.Private Label Expertise

Offering custom logos, trims, packaging, and label design to build strong brand identity.

6.Full In-House Processes

Fabric inspection, washing, cutting, printing, sewing, down filling, and packaging—all handled under one roof.

7.Real-Time Quality Control

We monitor every production stage to identify bottlenecks and guarantee on-time delivery.

8.Lead Times That Work for You

Samples in 7–14 days

Bulk production in 30 days

Testimonials & Client Experiences

Over the past two decades, Ginwen has supported a wide spectrum of clients:

Start-Up Outdoor Brands: Provided low-MOQ waterproof jackets with down filling that allowed new players to enter competitive markets quickly.

Fashion Retailers: Delivered stylish waterproof trench coats and city parkas that combined technical function with runway-ready design.

Global Wholesalers: Scaled production of 50,000+ waterproof jackets in a single run while maintaining consistent quality and strict deadlines.

Our consistent delivery has built long-term trust. Many of our clients renew contracts year after year, recognizing the advantage of working with a partner who combines flexibility, technical expertise, and scalable capacity.

The Role of Down Filling in Performance Waterproof Jackets

While many waterproof jackets are designed as lightweight shells, down filling remains an essential feature for brands targeting cold-weather markets.

Advantages of Down Filling in Waterproof Jackets:

Provides unmatched warmth-to-weight ratio.

Enhances comfort in harsh winter climates.

Offers premium value positioning for brands seeking higher retail price points.

At Ginwen, we integrate down filling into a wide range of waterproof jacket designs, from alpine parkas to insulated city coats. We also offer synthetic insulation options for brands targeting vegan or budget-conscious markets.

The ability to customize insulation type, weight, and distribution ensures that every client receives a jacket optimized for its target audience.

Why Brands & Retailers Choose Ginwen

Choosing a manufacturing partner is more than just comparing price quotes—it’s about aligning with a factory that understands your long-term vision.

Key reasons why brands choose Ginwen as their waterproof jacket manufacturer:

Experience: 20+ years of expertise in waterproof and insulated outerwear.

Flexibility: MOQ from 1 piece allows start-ups to test markets with minimal risk.

Capacity: Automated facilities producing 500,000 jackets monthly.

Innovation: Strong CAD development team for rapid prototyping.

Sustainability: Integration of recycled fabrics, eco-friendly coatings, and RDS-certified down filling.

Global Service: Supporting clients across Europe, North America, and Australia.

With our proven track record, we are positioned as the go-to partner for brands that demand quality, scalability, and ethical manufacturing.

Conclusion: Partner with Ginwen Today

As the market for waterproof jackets grows, the choice of manufacturing partner becomes even more critical. Working with a certified, experienced, and flexible factory can ensure that your products stand out in a competitive landscape.

At Ginwen, we combine low MOQ flexibility, massive production scalability, and cutting-edge material innovation to deliver waterproof jackets that align with your brand’s identity and customer expectations.

Whether you are launching a small capsule collection or preparing a large-scale wholesale order, our OEM & ODM services guarantee both efficiency and excellence.

📍 Get Started Today:

Explore our Custom Waterproof Jackets collection, learn more about our OEM & ODM Service, or Contact Us directly to discuss your project.

Your brand deserves a manufacturing partner who delivers more than just jackets—we deliver confidence, quality, and growth opportunities.